4D Printing: A step in the future

Over the last few decades, 3D printing has revolutionised the manufacturing industry by allowing designers to create complex, customisable objects in a fraction of the time and cost of traditional manufacturing methods. However, a new technology called 4D printing is taking this one step further by adding an extra dimension - time - to the printing process.

What is 4D printing?

4D printing is a process that uses smart materials that can change their shape over time when exposed to certain environmental conditions such as heat, moisture, or light. This allows 4D printed objects to transform, self-assemble, or self-repair without any additional programming or external control.

The concept of 4D printing was first proposed in 2013 by a team of researchers at Harvard University's Wyss Institute for Biologically Inspired Engineering. Since then, it has been applied in various fields, including aerospace, architecture, and medicine.

How does 4D printing work?

4D printing uses the same basic technology as 3D printing, but with the added capability of using smart materials. The process starts with a digital design of the object, which is then converted into a code that can be read by the printer.

The printer uses a combination of materials such as hydrogels, shape-memory alloys, and 3D printed smart polymers to create the final object. These materials are designed to respond to external stimuli, such as temperature, humidity, or light, causing them to change shape, bend, or contract in a predetermined manner.

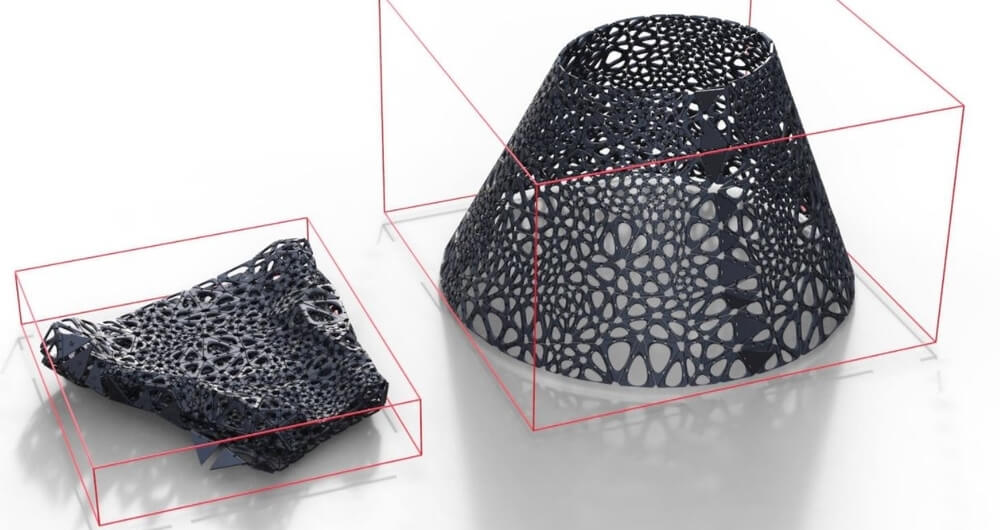

Once printed, the object is left to react to the environmental conditions, causing it to change its shape, size, or texture. For example, a 4D printed flower may start as a flat object, but once exposed to water, it will bloom into a three-dimensional shape, mimicking the behaviour of a real flower.

Applications of 4D printing

The potential applications of 4D printing are vast and varied. Here are a few examples:

- Self-assembling structures: 4D printing can be used to create self-assembling structures that can adapt to changing environmental conditions. This can be useful in areas such as construction, where structures can be designed to respond to weather changes.

- Medical implants: 4D printing can be used to create medical implants that can change shape and size over time, such as stents or prosthetic devices.

- Smart clothing: 4D printing can be used to create clothing that can adapt to different environmental conditions, such as jackets that can change their insulation properties based on the temperature.

- Aerospace: 4D printing can be used to create space structures that can unfold themselves in space, or shape-memory alloys that can be used for actuation or energy harvesting.

Challenges and limitations of 4D printing

While 4D printing has many potential applications, there are also several challenges and limitations that need to be addressed. Some of these include:

Material limitations: The range of materials that can be used for 4D printing is currently limited, and the cost of smart materials can be high.

Design complexity: 4D printing requires more complex design and simulation tools than 3D printing, which can increase the time and cost of development.

Environmental control: The properties of smart materials can be affected by external factors such as humidity and temperature, which can affect the final shape of the printed object.

Regulatory approval: The use of 4D printed medical devices and implants may require regulatory approval, which can be a lengthy and expensive process.Conclusion

4D printing is a relatively new technology that has the potential to transform the manufacturing industry in ways that previously were thought to be impossible. With its ability to create self-assembling structures, adaptive medical implants, and smart clothing, 4D printing has opened up a world of new possibilities. However, further research is needed to overcome the challenges and limitations of the technology before it becomes widely adopted in industry.Thank you,

Aarav Iyer

References:

(1) Sculpteo (Fig. 1 + content)

(2) Wikipedia